Speedgrip gets to grips with the issue of change over time with new Quick Change Adaptor

One of the traditional issues facing operators of CNC lathes, who are involved with smaller batch sizes, is that of change over time of workholding devices. There is the time involved with disassembly, cleaning, checking and reassembly which all adds to significant time delay and subsequent loss in productivity.

The need for shorter part runs and just in time manufacturing has exacerbated the need for versatile and quick change over workholding systems with minimal downtime. There are a number of systems currently in the marketplace which offer quick change adaptors and chucks, but the monetary investment required is, in most cases, prohibitive. There are also marked differences in the amount of time actually saved.

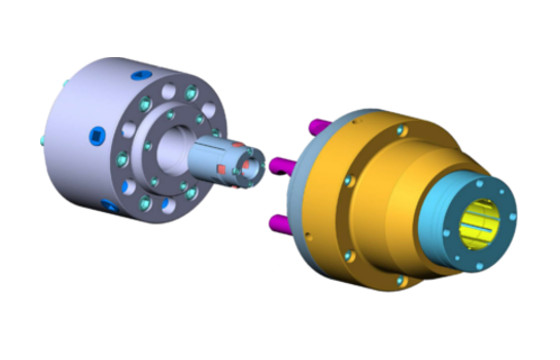

This is where Speedgrip’s Quick Change Adaptor comes into play. Using the industry tried and trusted Camlock technology with a carrier and receiver, it provides a solution that is accurate, fast to convert between workholding methods, and importantly very affordable.

You can now change over between power jaw chucks, collet chucks, expanding mandrel chucks or your face-driver quickly and easily. As an example, changing from a power jaw chuck to a collet chuck can be achieved in less than 5 minutes – an operation that would have taken around an hour using the conventional method.

Installation is simplicity itself. Mount the Camlock Adapter/Receiver to the spindle and then connect the Retainer/Connector assembly to the drawtube. A Camlock adaptor carrier is then fitted to the required jaw chuck, ID collet chuck, OD collet chuck, or face-driver with its retention knob and you are then ready to go.

To change over, you simply release the cam studs, move the drawtube forward, remove one chuck, clean, slide on the other, tighten the studs, retract the drawtube and in 5 minutes you have a completely different workholding system.

“Anything that can assist CNC operators boost their productivity is welcome news. The great thing about the Speedgrip Quick Change Adaptor is that it massively speeds up change over time, but at the same time remains affordable to all types of manufacturers both big and small,” Dimac Managing Director, Paul Fowler pointed out.

Dimac, Australia’s largest supplier of CNC machine tool accessories and workholding solutions, is the sole distributor for Speedgrip in Australia and New Zealand.

The US Speedgrip Chuck Company was founded in 1946, and all Speedgrip products are produced in their 43,000 square foot manufacturing facilities in Elkhart, Indiana. The company delivers premier engineered workholding solutions and its products are renowned for delivering the highest levels of quality and productivity for customers in every industry, where metal cutting is a part of the manufacturing process.

“We are proud to be Speedgrip’s sole distributor, and I know that the Quick Change Adaptor is going find a ready market with a wide range of manufacturers looking to boost both their productivity and workplace efficiency,” Mr Fowler went on to say.

“Like all the products we sell, the Speedgrip range will have the full back up and support of Dimac technical personnel to ensure the products are installed correctly and operate at optimum performance,” Mr Fowler concluded.

More information at:

https://www.dimac.com.au/product-category/turning/workholding-turning/quick-change-adapter/