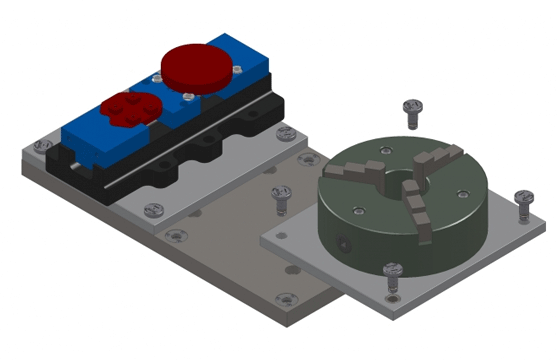

Ball Lock mounting system for flexible vice setups

Turning to a ball lock quick-change mounting system reduces set-up time and speeds changeovers, generating significant savings for workshops.

Many SMEs and job shops are faced with producing a variety of parts in a range of quantities, which means that time spent performing multiple setups on different machining centres can cause pre-machining bottlenecks and adversely affect the bottom line.

Dimac Tooling recommends investing in a ball lock quick-change mounting system, which addresses workshops’ challenges with vice setup flexibility. The ball lock quick-change fixturing system provides a method of quickly and accurately locating fixtures onto machine tables. It enables operators to quickly and easily change-over all mills or VMCs as needed to accommodate different jobs. As a result, setup times can be reduced by 20 to 50%, depending on the part. Moreover, the system can also contribute additional benefits, such as reducing scrap and improved machining accuracy.